Ask a Question. Get a Quote.

Get answers for your process.

Contact us

The ACCU-CHILL® combo chiller bulk chilling system provides consistent, precise delivery of CO2 snow when packing product into bulk bins. Snow and product are packed evenly – ensuring no over-cooling nor hot spots in the bin. This significantly improves product quality, yield, and incidents of out of specification products due to becoming too warm or too cold (to the point of being frozen). More on the Combo Chiller

Controlling temperature in the mixer

The ACCU-CHILL® CBC cryogen injection mixer system, either in batch or continuous processing, is a proprietary, bottom injection system that uses liquid nitrogen and provides improved efficiency and performance compared to older technologies. Cryogenic carbon dioxide or liquid nitrogen used in your mixing operation keeps your product at an optimal temperature – slowing the growth of bacteria. Additional information about the CBC system

Optimizing Product Quality

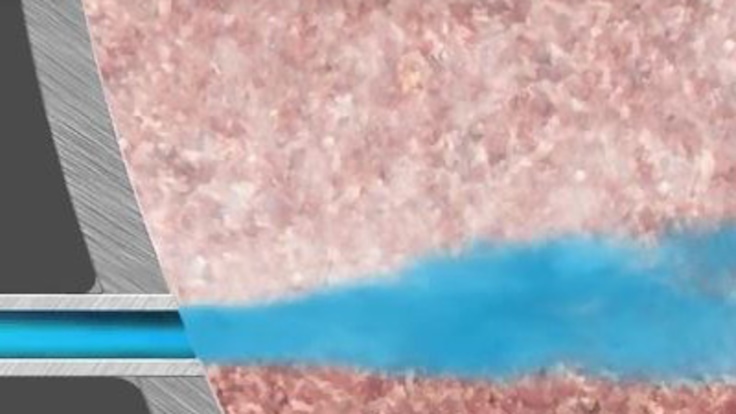

The ACCU-CHILL® LXC injection system is designed to deliver cryogen deep into the product, resulting in a larger amount of cryogen transfer to the mixture and up to a 33% improvement in cooling efficiency. This allows the processor to inject just the right amount of cryogen for continuous mixing or blending to keep the mixture at a uniform temperature. Heat generated during mixing and grinding can accelerate bacterial growth and lead to off-flavors, decreased shelf life and spoilage. Consistent mix temperatures are essential for making formed products with accurate and consistent dimensions and weights. Properly chilled product ensures the perfect blending of product, fats, flavorings and spices - all at the targeted temperature to preserve quality, texture and flavor. Read more about the LXC System

Removing heat with carbon dioxide snow is an economical, precise way to cool your product at any point in your production. Linde snow dispensing devices are available in a wide range of sizes and types, so there is a snow delivery system to meet your needs. The snow horn devices allow for precise snow application to your poultry product for immediate chilling during transfer or preparation prior to shipping.

Linde gases are used for freezing, chilling and cooling food products, pressurizing & carbonating beverages, boosting greenhouse growing yields and more. Related gases

Linde is always expanding gas applications and developing improved equipment systems to keep in step with our customer's growth. We're guided by our core competencies. Innovations and Competencies